SuperMax® II Rope

SuperMax® II Rope

|

SuperMax® II Rope

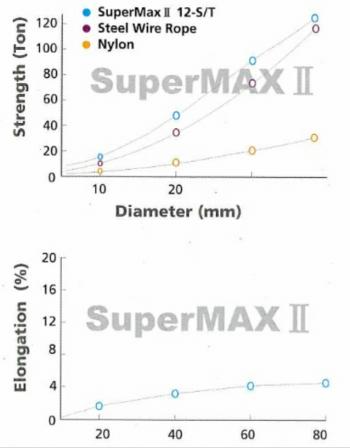

Breaking Strength

Elongation Table

|

*SuperMax® II is the latest development of ultra high modecular weight polyethylene (UHMWPE), Dyneema® SK-75, fiber braided rope utilizing DSR's own rope design and manufacturing know-how's.

Maximum strength to weight ratio, and strength comparable to steel wire rope!

Breaking Load (%)

|

Specification of SuperMax® II Rope | |||||||

| Diameter | Circumference | Weight | Breaking Strength | ||||||

| INCH | MM | INCH | MM | LBS/100FT | AVG(LBS) | MIN(LBS) | |||

| 1/4 | 6 | 3/4 | 18 | 1.51 | 8,910 | 8,100 | |||

| 5/16 | 8 | 1 | 24 | 2.46 | 13,750 | 12,500 | |||

| 3/8 | 9 | 1-1/8 | 27 | 3.45 | 19,690 | 17,900 | |||

| 7/16 | 11 | 1-1/4 | 33 | 4.16 | 23,650 | 21,500 | |||

| 1/2 | 12 | 1-1/2 | 36 | 6.2 | 35,090 | 31,900 | |||

| 9/16 | 14 | 1-3/4 | 42 | 7.6 | 42,570 | 38,700 | |||

| 5/8 | 16 | 2 | 48 | 10.3 | 57,530 | 52,300 | |||

| 3/4 | 18 | 2-1/4 | 54 | 13.9 | 75,790 | 68,900 | |||

| 13/16 | 20 | 2-1/2 | 60 | 15.9 | 83,050 | 75,500 | |||

| 7/8 | 22 | 2-3/4 | 66 | 19.5 | 103,840 | 94,400 | |||

| 1 | 24 | 3 | 72 | 23.4 | 123,200 | 112,000 | |||

| 1-1/16 | 26 | 3-1/4 | 78 | 27.5 | 143,000 | 130,000 | |||

| 1-1/8 | 28 | 3-1/2 | 84 | 31.7 | 163,900 | 149,000 | |||

| 1-1/4 | 30 | 3-3/4 | 90 | 36.3 | 184,800 | 168,000 | |||

| 1-5/16 | 32 | 4 | 96 | 42.9 | 216,700 | 197,000 | |||

| 1-1/2 | 36 | 4-1/2 | 108 | 49.8 | 247,500 | 225,000 | |||

| 1-5/8 | 40 | 5 | 120 | 65.7 | 323,400 | 294,000 | |||

| 1-3/4 | 44 | 5-1/2 | 132 | 72.7 | 352,000 | 320,000 | |||

| 2 | 48 | 6 | 144 | 82.8 | 398,200 | 362,000 | |||

| 2-1/8 | 52 | 6-1/2 | 156 | 93.9 | 479,600 | 436,000 | |||

| 2-1/4 | 56 | 7 | 168 | 114.6 | 539,000 | 490,000 | |||

| 2-1/2 | 60 | 7-1/2 | 180 | 127 | 594,000 | 540,000 | |||

| 2-5/8 | 64 | 8 | 192 | 145.8 | 667,700 | 607,000 | |||

| 2-3/4 | 68 | 8-1/2 | 204 | 163 | 740,300 | 673,000 | |||

| 3 | 72 | 9 | 216 | 196.5 | 874,500 | 795,000 | |||

| 3-1/4 | 80 | 10 | 240 | 240.6 | 1,053,800 | 958,000 | |||

|

Characteristics

Applications |

• Maximum strength to weight ratio, and strength comparable to steel wire rope. • Manufactured tested according to ISO and BSEN standards.

|